MRP software, or Material Requirements Planning software, is revolutionizing how businesses manage their inventory and production processes. It’s no longer just about tracking parts; it’s about predicting demand, optimizing resources, and ultimately, boosting profitability. This powerful tool allows companies to forecast future needs, schedule production efficiently, and ensure they have the right materials at the right time, minimizing waste and maximizing output.

From manufacturing giants to smaller enterprises, MRP software is proving its worth in a competitive market.

Understanding MRP software goes beyond simply knowing its features; it’s about grasping its potential to transform your operations. This involves understanding the different types of systems available (open-loop and closed-loop), mastering the intricacies of bill of materials (BOM) management, and effectively leveraging capacity planning to avoid bottlenecks. Successful implementation requires careful planning, employee training, and a clear understanding of the associated costs and potential challenges.

Defining MRP Software

Material Requirements Planning (MRP) software is a crucial tool for businesses that need to manage their inventory efficiently and effectively. It’s a powerful system designed to optimize the production process by ensuring that the right materials are available at the right time and in the right quantities. This minimizes waste, reduces lead times, and ultimately boosts profitability. Think of it as the brain of a manufacturing operation, meticulously coordinating the flow of materials from raw goods to finished products.MRP software achieves this through a complex interplay of data and algorithms.

It integrates data from various sources, including sales forecasts, bills of materials (BOMs), inventory levels, and production schedules. Using this information, it calculates the precise quantities of materials needed for each stage of production, scheduling their procurement and ensuring a smooth, uninterrupted workflow. This allows companies to accurately predict demand, prevent stockouts, and avoid overstocking, ultimately leading to significant cost savings.

Core Functionality of MRP Software

The core functionality of MRP software revolves around demand forecasting, inventory management, and production scheduling. It utilizes sophisticated algorithms to analyze sales data and predict future demand, allowing businesses to proactively order materials and schedule production accordingly. The software also tracks inventory levels in real-time, alerting managers to potential shortages or surpluses. Finally, it creates detailed production schedules, optimizing resource allocation and ensuring timely completion of orders.

The ability to manage capacity, analyze lead times, and provide real-time visibility into the entire production process is what sets MRP apart.

Types of MRP Systems

MRP systems can be broadly categorized into open-loop and closed-loop systems. Open-loop MRP systems focus primarily on planning and scheduling based on predicted demand. They are simpler to implement but offer less real-time control and adaptability. Closed-loop MRP systems, on the other hand, incorporate feedback mechanisms to adjust plans based on actual production data and inventory levels. This closed-loop approach provides greater accuracy and responsiveness to changes in demand or production.

The choice between these systems depends heavily on the complexity of the manufacturing process and the level of real-time control required.

Industries Utilizing MRP Software

MRP software finds extensive application across various industries, particularly those involved in manufacturing and production. The automotive industry, for example, relies heavily on MRP to manage the intricate supply chains involved in car manufacturing. Similarly, the electronics industry uses MRP to coordinate the procurement and assembly of components for electronic devices. Aerospace, pharmaceuticals, and food processing are further examples of sectors where precise material planning is crucial and MRP plays a vital role in optimizing operations.

The common thread across these industries is the need for precise inventory control and efficient production scheduling, which MRP excels at providing.

Comparison with Other Inventory Management Systems

While MRP software shares some similarities with other inventory management systems, it differs significantly in its scope and functionality. Simpler inventory management systems primarily focus on tracking inventory levels and managing stock. MRP, however, goes beyond simple tracking, incorporating demand forecasting, production scheduling, and capacity planning. Enterprise Resource Planning (ERP) systems often integrate MRP functionality, providing a more comprehensive solution for managing all aspects of a business.

However, standalone MRP systems remain a valuable tool for businesses with a strong focus on manufacturing and production optimization, offering specialized capabilities for managing complex supply chains.

Key Features of MRP Software

MRP software, or Material Requirements Planning software, is more than just a spreadsheet; it’s the brains behind efficient production. A robust MRP system streamlines operations, minimizing waste and maximizing output. Understanding its core features is key to leveraging its full potential for any manufacturing business, big or small.

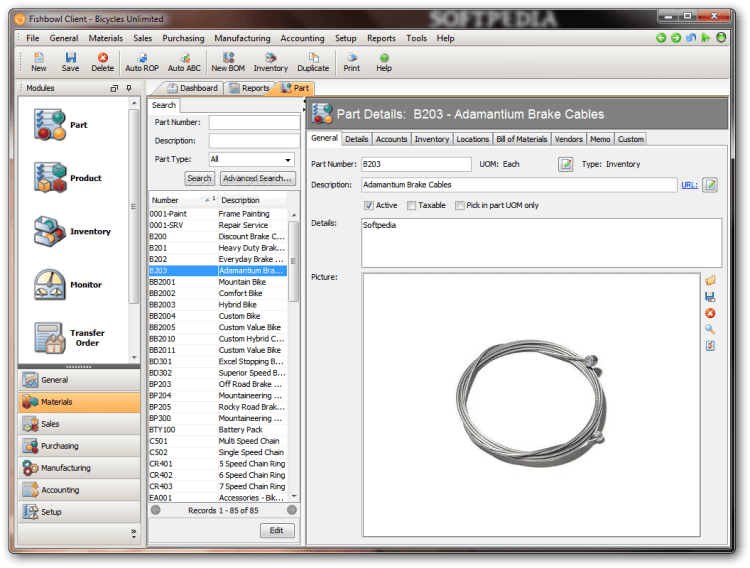

Bill of Materials (BOM) Management

The Bill of Materials is the backbone of any MRP system. It’s a comprehensive list of all the raw materials, components, sub-assemblies, intermediate assemblies, sub-components, parts, and the quantities of each needed to manufacture one unit of a finished product. Effective BOM management within MRP software allows for accurate forecasting of material needs, minimizing stockouts and preventing overstocking.

The software allows for easy updates and version control of BOMs, ensuring that the production process always uses the most current and accurate information. Changes to the BOM, such as substituting a component, are immediately reflected in the entire production plan.

Capacity Planning

Capacity planning in MRP involves analyzing the production capacity of your resources—machinery, labor, and space—to ensure they can meet the demands Artikeld in the production schedule. MRP software helps predict potential bottlenecks by comparing the planned production volume with the available resources. This allows for proactive adjustments, such as scheduling overtime, investing in new equipment, or outsourcing certain tasks, preventing delays and ensuring timely delivery of finished goods.

For example, if the software identifies a shortage of skilled labor for a specific task during peak production, it can alert managers to hire temporary staff or re-allocate existing resources.

Production Scheduling and Resource Allocation

MRP software excels at optimizing production schedules and allocating resources effectively. Based on the BOM, demand forecasts, and capacity constraints, the software generates a detailed production schedule that Artikels the sequence of operations, the required resources, and the deadlines for each task. This ensures that materials are available when needed, machines are utilized efficiently, and labor is assigned optimally.

The software also helps in managing work-in-progress (WIP) inventory by tracking the progress of each production order and identifying potential delays. Imagine a furniture manufacturer using MRP; the software would schedule the cutting of wood, the assembly of parts, and the finishing processes, ensuring all resources – wood, tools, and carpenters – are allocated effectively to meet delivery deadlines.

Comparison of MRP Software Vendors

Choosing the right MRP software is crucial. Here’s a comparison of three popular vendors, highlighting key features:

| Feature | Vendor A | Vendor B | Vendor C |

|---|---|---|---|

| BOM Management | Robust, with version control and change management | Good, with basic version control | Basic, limited version control |

| Capacity Planning | Advanced simulation and what-if analysis | Standard capacity planning tools | Limited capacity planning features |

| Production Scheduling | Sophisticated scheduling algorithms, real-time tracking | Standard Gantt charts and scheduling tools | Basic scheduling functionality |

| Integration Capabilities | Seamless integration with ERP and other systems | Limited integration capabilities | Integration with select systems only |

Benefits and Challenges of MRP Software

Implementing Material Requirements Planning (MRP) software offers a significant opportunity for businesses to streamline their operations and boost profitability. However, like any significant technological investment, it comes with its own set of hurdles. Understanding both the potential gains and the potential pitfalls is crucial for making an informed decision.MRP software, when implemented correctly, can revolutionize a company’s supply chain management, leading to substantial improvements across various departments.

Let’s delve into the specific advantages and disadvantages, along with the associated costs and return on investment.

Tangible Benefits of MRP Software Implementation

The benefits of MRP software extend far beyond simple inventory management. Successful implementation leads to demonstrably improved efficiency, reduced costs, and enhanced customer satisfaction. These benefits translate directly to a stronger bottom line.

- Reduced Inventory Costs: MRP optimizes inventory levels by accurately forecasting demand and minimizing overstocking or stockouts. This directly translates to lower storage costs, reduced obsolescence, and less capital tied up in inventory. For example, a manufacturing company using MRP might see a 15% reduction in inventory holding costs within a year.

- Improved Production Scheduling: MRP software enables more precise production scheduling, leading to smoother workflows and reduced lead times. This means faster order fulfillment and improved responsiveness to customer demands. A furniture manufacturer, for instance, could decrease production lead times by 20% after implementing MRP, leading to increased sales and customer satisfaction.

- Enhanced On-Time Delivery: By accurately predicting material needs and optimizing production schedules, MRP significantly improves on-time delivery rates. This strengthens customer relationships and builds brand loyalty. A food processing company, for example, could increase its on-time delivery rate from 80% to 95% after implementing an MRP system.

- Better Capacity Planning: MRP provides valuable insights into resource utilization, allowing businesses to optimize capacity planning and avoid bottlenecks. This leads to increased efficiency and improved resource allocation. A clothing manufacturer, for instance, could utilize its machinery more efficiently, leading to a 10% increase in overall production.

Challenges Associated with MRP Implementation and Maintenance

While the potential benefits are significant, the implementation and maintenance of MRP software present several challenges that businesses must consider. Careful planning and execution are crucial for successful adoption.

- High Initial Investment: The cost of purchasing and implementing MRP software can be substantial, encompassing software licenses, hardware upgrades, consulting fees, and employee training. This initial investment can be a significant barrier for smaller businesses.

- Data Accuracy and Integrity: MRP systems rely heavily on accurate and up-to-date data. Inaccurate or incomplete data can lead to flawed forecasts and inefficient operations. Maintaining data accuracy requires meticulous data entry and regular data validation.

- System Complexity and Integration: MRP software can be complex to implement and integrate with existing systems. This requires specialized expertise and can lead to delays and unexpected costs. Thorough planning and careful selection of an implementation partner are essential.

- Resistance to Change: Employees may resist adopting new software and processes. Effective change management strategies, including thorough training and communication, are crucial for overcoming this resistance.

Costs Associated with Purchasing and Maintaining MRP Software

The total cost of ownership (TCO) for MRP software extends beyond the initial purchase price. Ongoing maintenance, upgrades, support, and training contribute significantly to the overall cost. These costs should be factored into the budget when considering an MRP implementation.The initial investment can range from several thousand dollars for smaller businesses to hundreds of thousands for larger enterprises.

Ongoing maintenance costs typically include annual software maintenance fees, support contracts, and potential upgrades. The cost of training employees can also be significant, especially for larger organizations.

Return on Investment (ROI) of MRP Software Compared to Alternatives

The ROI of MRP software varies depending on the specific business, the scale of implementation, and the efficiency of the implementation process. However, the potential for significant cost savings and improved efficiency makes it a compelling investment for many businesses. Compared to alternative solutions, such as manual inventory management or less sophisticated planning tools, MRP often offers a superior ROI due to its ability to automate processes, optimize resource allocation, and improve forecasting accuracy.

MRP software excels at managing inventory and production, ensuring a smooth flow of goods. However, for a truly holistic view of your e-commerce operations, integrating it with a robust ERP system is key; understanding the nuances of erp in ecommerce can significantly enhance your MRP’s effectiveness. Ultimately, a well-integrated system allows for better forecasting and optimized resource allocation, maximizing the benefits of your MRP software.

A detailed cost-benefit analysis, comparing the projected savings against the total cost of ownership, is crucial for determining the actual ROI in a specific context. For example, a company might project a 20% reduction in inventory costs and a 15% increase in on-time delivery within two years, leading to a significant positive ROI compared to continuing with their existing, less efficient system.

Advanced MRP Software Capabilities

Stepping beyond the basics, advanced MRP systems are transforming how businesses manage their production and inventory. These systems leverage cutting-edge technologies to offer unparalleled levels of efficiency, accuracy, and strategic insight, ultimately leading to a significant competitive advantage. Let’s delve into the capabilities that set these advanced systems apart.Advanced MRP systems are no longer just about scheduling and tracking; they’re about predicting and optimizing.

This shift is driven by the integration of artificial intelligence (AI) and machine learning (ML), predictive analytics, and seamless integration with other enterprise systems. These capabilities allow for a proactive, data-driven approach to manufacturing, minimizing waste and maximizing profitability.

AI and Machine Learning in Advanced MRP

AI and ML algorithms analyze vast amounts of historical data, identifying patterns and trends that would be impossible for humans to discern. This enables more accurate demand forecasting, optimized production scheduling, and proactive identification of potential bottlenecks or disruptions. For example, an AI-powered MRP system might detect a seasonal surge in demand for a specific product weeks in advance, allowing for adjustments in production capacity and raw material procurement to prevent stockouts.

Furthermore, ML algorithms can continuously learn and improve their predictive accuracy over time, becoming increasingly sophisticated with each production cycle. This self-learning capability is a key differentiator of advanced MRP systems.

Predictive Analytics and Forecasting Accuracy, Mrp software

Predictive analytics plays a crucial role in improving forecasting accuracy within advanced MRP systems. By analyzing historical sales data, market trends, economic indicators, and even social media sentiment, these systems can generate more accurate demand forecasts. This reduces the risk of overstocking or understocking, minimizing holding costs and preventing lost sales opportunities. For instance, an advanced MRP system might predict a potential drop in demand for a particular product due to the launch of a competing product, prompting the manufacturer to adjust production schedules and prevent excess inventory buildup.

The integration of external data sources, such as weather patterns affecting raw material availability, further enhances the accuracy of these predictions.

Integration with ERP Systems

The true power of advanced MRP systems is unlocked through seamless integration with other Enterprise Resource Planning (ERP) systems. This integration allows for a holistic view of the entire business, connecting production planning with finance, sales, and customer relationship management (CRM). This unified approach streamlines processes, reduces data silos, and improves decision-making across all departments. For example, real-time sales data from the CRM system can be directly fed into the MRP system, allowing for immediate adjustments to production schedules based on actual customer demand.

This eliminates delays and ensures that production aligns perfectly with sales targets.

Hypothetical Scenario: Optimizing Production for a Seasonal Demand Spike

Imagine a company that manufactures winter coats. Using a traditional MRP system, they might struggle to accurately predict demand during the peak season, leading to either stockouts or excessive inventory. An advanced MRP system, however, can leverage predictive analytics and AI to analyze historical sales data, weather forecasts, and even social media trends to accurately forecast demand for the upcoming winter.

The system would then automatically adjust production schedules, optimize raw material procurement, and even alert the logistics team to prepare for increased shipping volume. The result would be a significant reduction in inventory costs, improved customer satisfaction due to timely product availability, and increased profitability. This proactive approach, enabled by advanced MRP capabilities, is a significant competitive advantage in today’s dynamic market.

Future Trends in MRP Software

MRP software is rapidly evolving, driven by the need for greater efficiency, agility, and responsiveness in today’s dynamic supply chains. The integration of advanced technologies and the increasing complexity of global manufacturing are shaping the future of this crucial software category. We’re moving beyond basic inventory management towards a more predictive and proactive approach, leveraging data analytics and artificial intelligence to optimize every stage of production.The impact of Industry 4.0 technologies, such as the Internet of Things (IoT), cloud computing, and artificial intelligence (AI), is fundamentally transforming MRP systems.

These technologies are enabling real-time visibility into the entire supply chain, facilitating better decision-making, and improving overall operational efficiency. This shift is not just about incremental improvements; it’s about a complete paradigm shift in how businesses manage their production and logistics.

Industry 4.0’s Influence on MRP Systems

Industry 4.0 technologies are deeply impacting MRP software, moving it beyond traditional functionalities. The integration of IoT sensors in manufacturing plants provides real-time data on machine performance, inventory levels, and production progress. This data feeds directly into the MRP system, enabling proactive adjustments to production schedules and resource allocation. For example, if a machine malfunctions, the system can automatically adjust the production schedule to minimize delays, preventing potential bottlenecks.

Cloud computing enhances accessibility and collaboration, allowing teams across different locations to access and update information simultaneously. This improves communication and coordination within the supply chain, reducing errors and improving responsiveness. AI algorithms analyze historical data and predict future demand, enabling more accurate forecasting and inventory planning. This reduces waste and improves inventory turnover, leading to significant cost savings.

Consider a company like Amazon, which uses sophisticated AI-powered MRP systems to manage its vast and complex global supply chain. Their ability to predict demand accurately and efficiently manage inventory is a direct result of their investment in advanced MRP technologies.

Predictive and Prescriptive Analytics in MRP

The future of MRP software lies in its ability to move beyond descriptive analytics (what happened) and diagnostic analytics (why it happened) to predictive and prescriptive analytics. Predictive analytics leverages machine learning algorithms to forecast future demand, identify potential risks, and optimize production schedules. This allows businesses to proactively address potential issues before they impact production. Prescriptive analytics goes a step further, suggesting optimal actions to take based on predicted outcomes.

For instance, if the system predicts a shortage of a particular component, it can suggest alternative suppliers or adjustments to the production schedule to mitigate the risk. This proactive approach minimizes disruptions and ensures consistent production. Companies adopting this approach are seeing significant improvements in their on-time delivery rates and overall operational efficiency.

Potential Future Features of MRP Software

The continuous evolution of technology will lead to significant advancements in MRP software capabilities. Several potential future features are on the horizon:

- Enhanced AI-driven forecasting: More accurate and granular demand forecasting, considering various factors like seasonality, economic trends, and social media sentiment.

- Blockchain integration: Enhanced transparency and traceability throughout the supply chain, improving security and reducing counterfeiting.

- Advanced simulation capabilities: Sophisticated simulations to test different scenarios and optimize production plans before implementation.

- Automated procurement and order management: Intelligent systems automatically generate purchase orders, track shipments, and manage supplier relationships.

- Integration with augmented and virtual reality (AR/VR): Providing real-time visualisations of production processes and inventory levels for improved decision-making and training.

- Improved sustainability features: Tracking and optimization of resource consumption, waste reduction, and carbon footprint.

Case Studies of MRP Software Implementation

Implementing Material Requirements Planning (MRP) software can be a game-changer for businesses across various sectors. Successful deployments often lead to significant improvements in efficiency, cost reduction, and overall profitability. Let’s delve into a real-world example to illustrate these benefits.

Successful MRP Implementation in the Automotive Industry

This case study focuses on “AutoTech,” a mid-sized automotive parts manufacturer experiencing challenges with inventory management and production scheduling. Before implementing MRP software, AutoTech relied on manual processes, leading to frequent stockouts, excess inventory, and production delays. This resulted in lost sales opportunities, increased storage costs, and dissatisfied customers. The company decided to implement an integrated MRP system to streamline its operations and address these issues.

Before MRP implementation, AutoTech experienced significant inventory discrepancies, leading to a 20% loss in potential sales due to stockouts and a 15% increase in storage costs due to excess inventory. Production lead times were unpredictable, averaging 14 days with frequent delays. Customer satisfaction scores were consistently low, reflecting the unreliable delivery times.

After implementing the MRP software, AutoTech saw a dramatic transformation in its operational efficiency. The system automated inventory tracking, optimized production scheduling, and improved forecasting accuracy. This allowed for better resource allocation, reduced waste, and improved on-time delivery.

Following the MRP implementation, AutoTech experienced a 10% increase in sales due to improved on-time delivery and reduced stockouts. Storage costs decreased by 8%, and production lead times were reduced to an average of 7 days. Customer satisfaction scores increased significantly, reflecting the improvement in delivery reliability. The overall impact was a noticeable increase in profitability and a more streamlined, efficient operation.

Visual Representation of AutoTech’s Transformation

Imagine two bar graphs side-by-side. The first graph (Before MRP) shows high bars representing inventory costs, production lead times, and stockout rates, alongside a low bar for customer satisfaction and sales. The second graph (After MRP) shows significantly reduced bars for inventory costs, lead times, and stockouts, with noticeably higher bars for customer satisfaction and sales. This visual representation clearly highlights the positive impact of the MRP software on AutoTech’s key performance indicators.

Key Metrics Demonstrating Improvement

| Metric | Before MRP | After MRP |

|---|---|---|

| Inventory Costs | $500,000 | $460,000 |

| Production Lead Time (days) | 14 | 7 |

| Stockout Rate | 10% | 2% |

| Customer Satisfaction Score | 65% | 85% |

| Sales Revenue | $2,000,000 | $2,200,000 |